Application examples

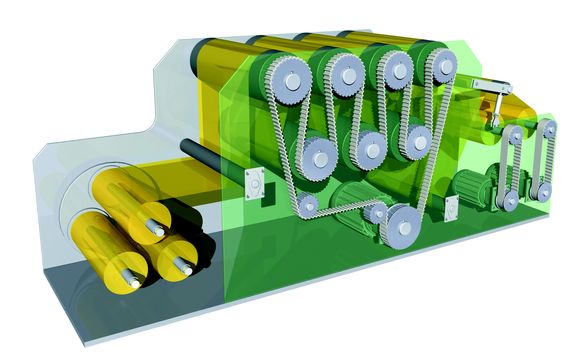

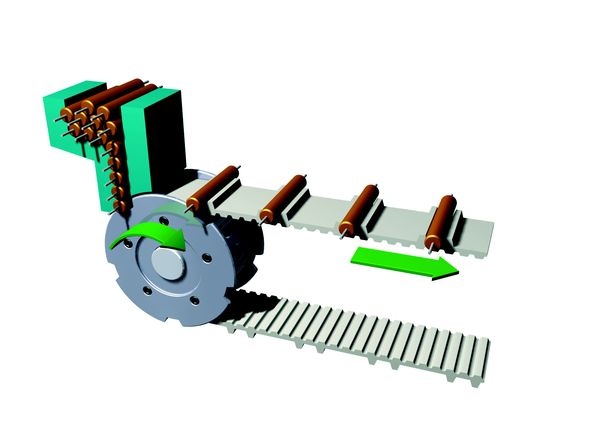

Film stretching unit

In a film stretching unit the films and belts are subject to targeted changes to their characteristic features. Due to the stretching process the molecular chains are aligning in pulling direction and the tensile strength is increased. The stretching process is carried out using heated rollers. We recommend that the change in speed of each following roller should amount to 3 to 3.5 %.

Design characteristic:

The rollers on the drive side are equipped with over-mounted pulleys. The number of teeth of pulleys arranged one after the other is reduced by 1: z = 33/32/31 and so on. The belt arrangement of the double-sided endless belt is similar to the film routing.

Transmission data:

BRECOFLEX TIMING BELT 50 T 20 / 7500 DL

Rotational speed n1 = 400 min-1

Transmission power P = 12 kW

Drive pulley assembly z1 = 36

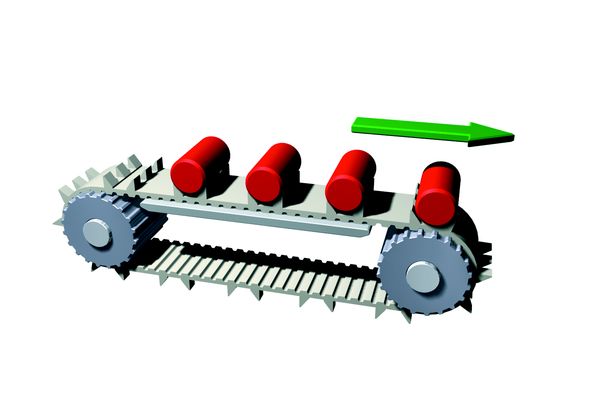

Product separation

Assembly belt