M (cam) clean cut

Note:

The article is specified on following pages. E. g. The selection of the belt width can be made. For the selection click on the "Inquiry basket" or on the CAD button. (see Help)

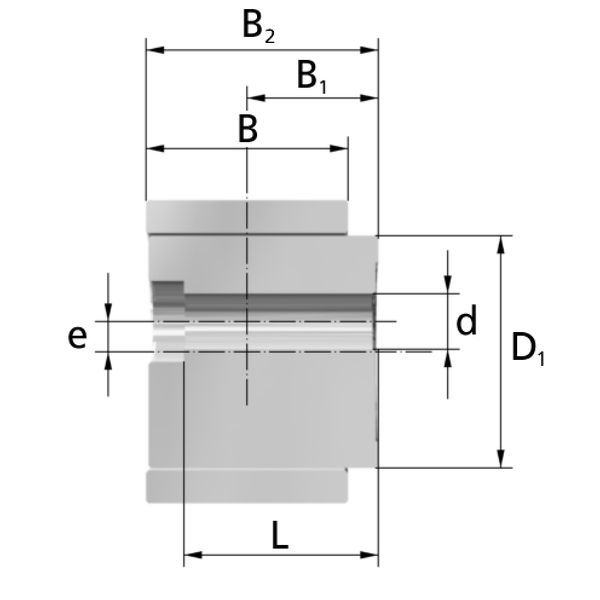

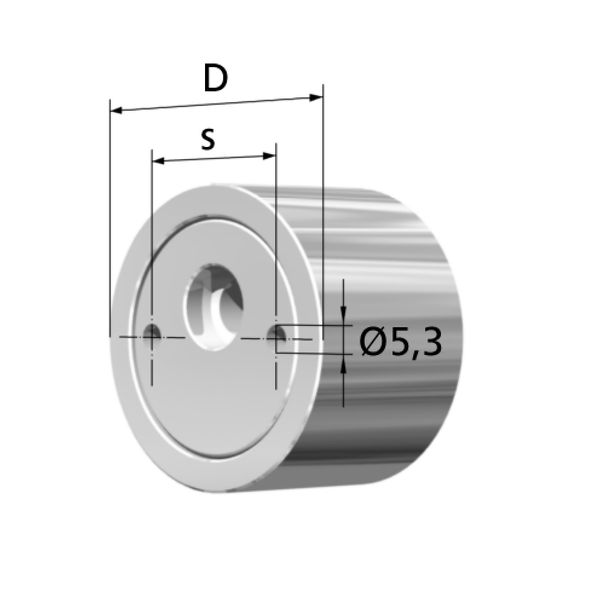

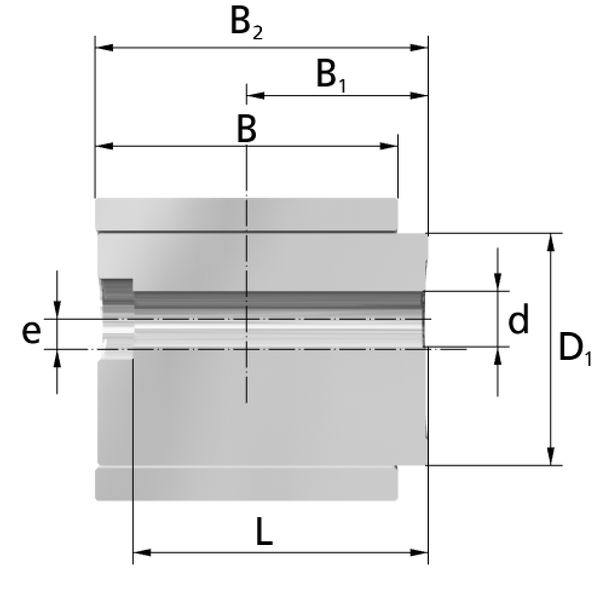

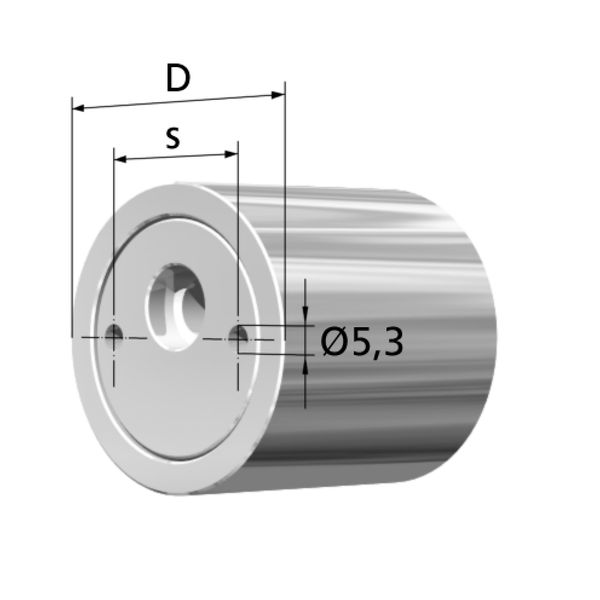

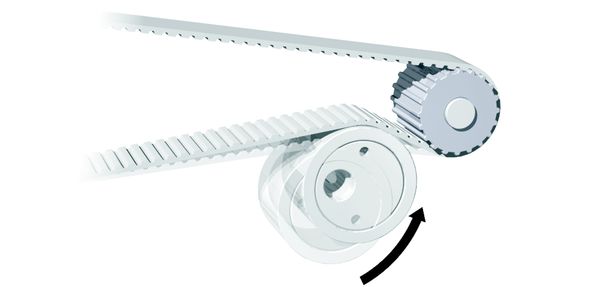

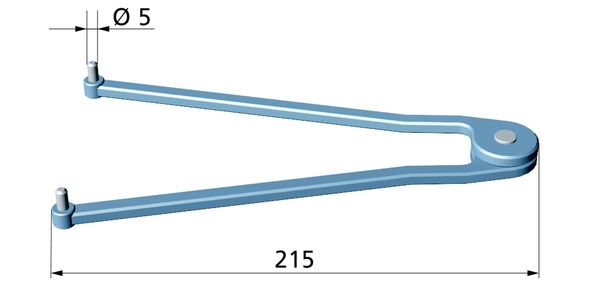

The MULCO tension roller Type M is an innovative development. It is available in 7 standard sizes. The tension rollers are distinguished by a rigid, vibration-resistant load bearing design. The forces acting by the belt pull are reliably absorbed by the generously dimensioned D1 base diameter. The ball race and the load bearing structure are made of AlCuMgPb (F38). The tension rollers are over-mounted on the machine wall. The eccentrical fitting results in an easy adjustment of the belt pre-tension force. To ensure the swivel motion around the mounting axle, the face spanner (picture on the right) can be used.

The MULCO tension rollers are fitted with high quality grooved ball bearings. The first filling of the bearings consists of a high-performance lithium saponified grease to ensure life time service. The greases are short-time temperature resistant up to 120°C. Permanent temperatures of 70°C and above will lead to a reduced useful life of the grease. The stated load bearing parameters refer to the entire tension roller on the basis of a centred belt load.

Cheese-head screws according to DIN 6912 can be used for machine wall mounting. The appropriate screw length depends on the fitting situation and the attendant surrounding structure. The table shows thread sizes and the recommenced strength of the cheese-head screws.

Please consider our warranty.