Information

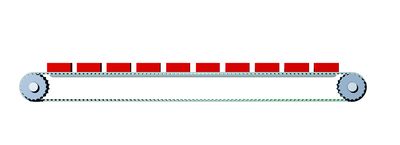

BRECO®-, BRECOFLEX®polyurethane timing belts have proven as an excellent transport medium. In the drive pulley assembly the pull-off force is reliably induced by the positive fit of the belt teeth. The steel cord tension members transmit high tensile forces.

The belt material polyurethane has abrasion and ageing resistant.

The bed plate

The belt span is deflected first by the load of the transported products. Bed plates are to be used as constructive mean. We offer bed plates with or without guide channels depending on the requested function. The timing belt friction coefficients are low.

The bed plates are available as a standard range, matched to the timing belt width. The preferred delivery length is 2000 mm. Cuts to length shorter than 2000 mm are available. Further dimensions on request.

Material

Our selected choice of material is low-pressure polyethylene. This material has a low friction coefficient and is also wear resistant.

The sliding friction value between standard polyurethane and low-pressure polyethylene is µ ~ 0.3.

The C profile is made of zinc plated sheet steel. The cut-out is intended for fastening screws. The C profile has no bore holes.

Installation information

Due to the relatively large expansion of the sliding material under temperature, provide expansion gaps in the rail structure. Approximative formula for the linear expansion of low-pressure polyethylene:

2mm/10°C temperature difference over 1000 mm of length.