Basis of calculation

Providing the following conditions of tooth strength (1.), tension member tensile strength (2.) and flexibility (3.) are met, then a maintenance-free timing belt operation can be expected.

1. (specific) Tooth shear strength

The specific tooth shear strength depends on the rotational speed. The maximum tooth shear strength is the limit load the belt tooth can cope with in continuous operation. The sizes for each individual timing belt type are shown in tables and graphs. The timing belt drive is correctly designed, when not exceeding the tooth shear strength. Generally, a special safety surplus is not necessary, see chapter "Safety factors".

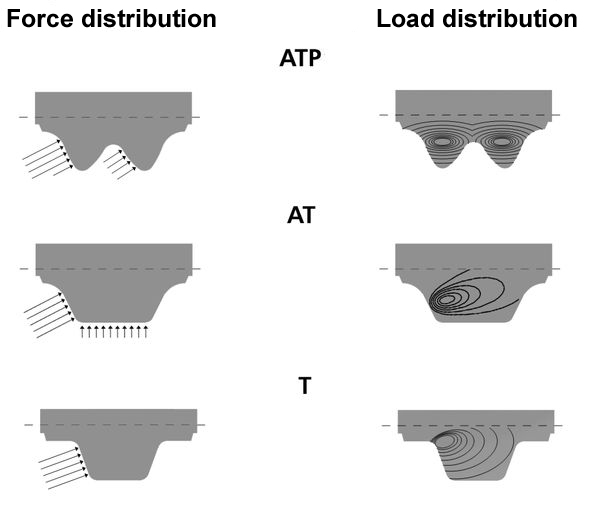

The high specific tooth strength of the ATP profile, for example, is achieved by the optimised force and load distribution. The affective force is distributed to two tooth faces.

The working loads can be distributed the better the more belt teeth are meshing in the pulley.

Due to the high pitch accuracy of BRECOFLEX® and CONTI® SYNCHROFLEX polyurethane timing belts, generally, it can be calculated with 12 belt teeth in mesh, should the number of teeth in mesh be respectively high enough.

2. Tension cord strength

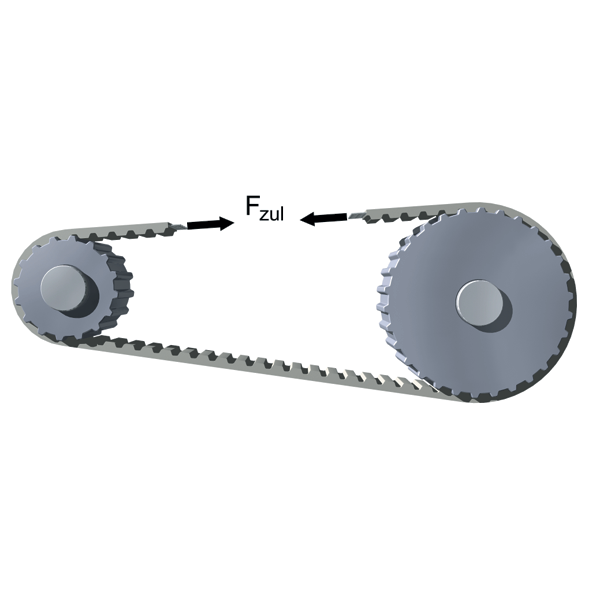

permitted tensile load of the belt cross-section

The timing belt is designed correctly when the maximum permitted tensile load in the steel cord member is not exceeded under operation conditions. The table values for Fzul refer to the constant loading.

3. Flexibility

Minimum number of teeth, minimum diameter

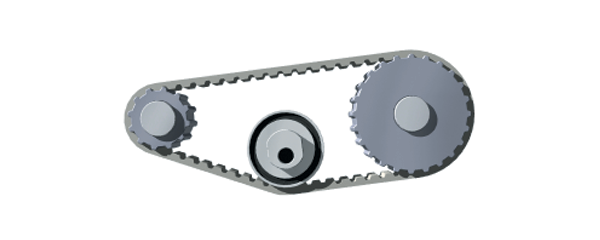

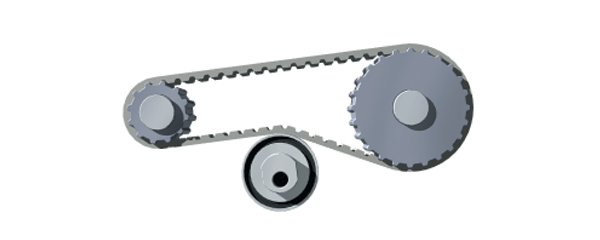

The recommended minimum number of teeth and/or the minimum diameter for a malfunction-free operation depends on the selected belt type. Take especially into consideration that the minimum number of teeth and/or the minimum diameter is higher when using a belt arrangement "with contraflexure" (e. g. due to a tension roller).