Belt guidance

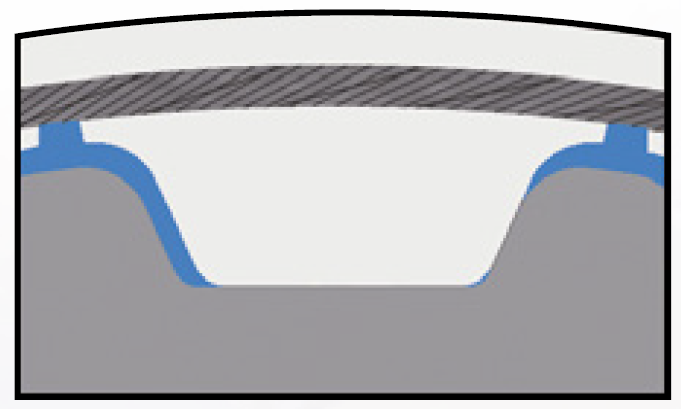

Timing belt guidance by flanges

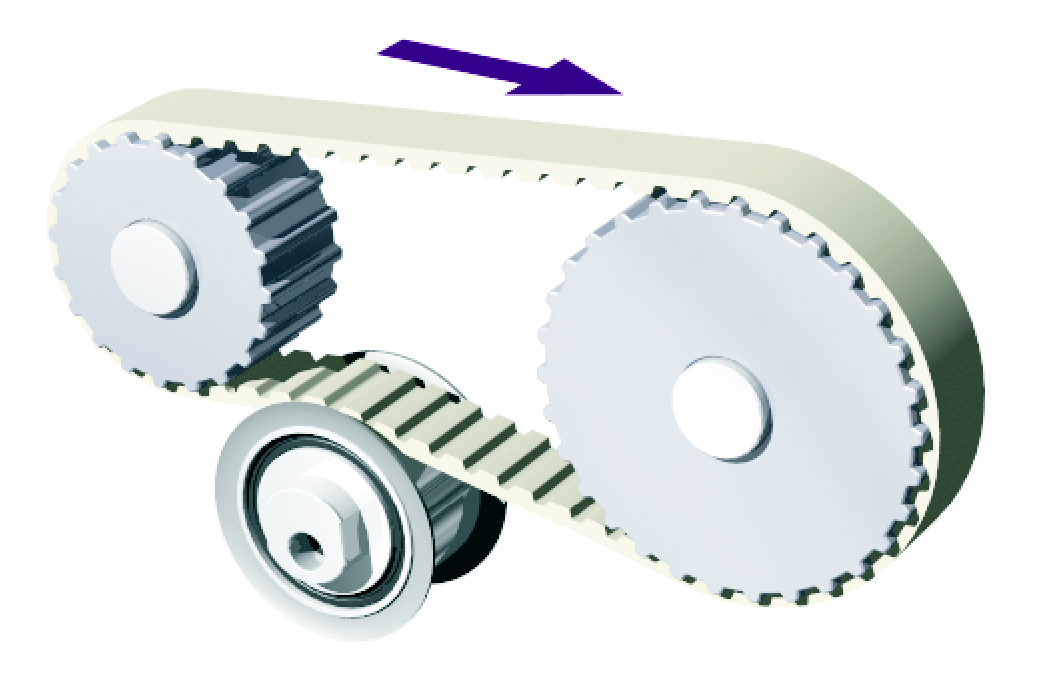

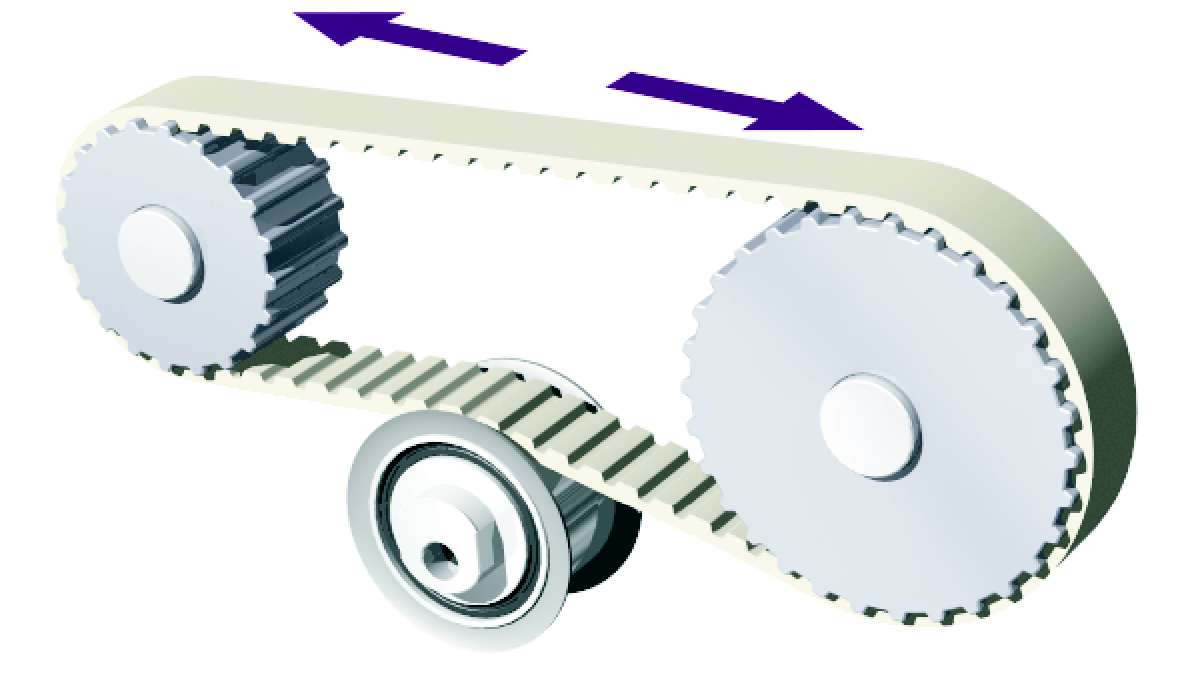

Timing belts must be guiding to eliminate the lateral wandering-off effect. Generally, the guidance is done by flanges.

The correct arrangement of the belt guidance is of an essential importance for a malfunction-free operation. Minimum lateral forces and low frictional losses are to be aspired.

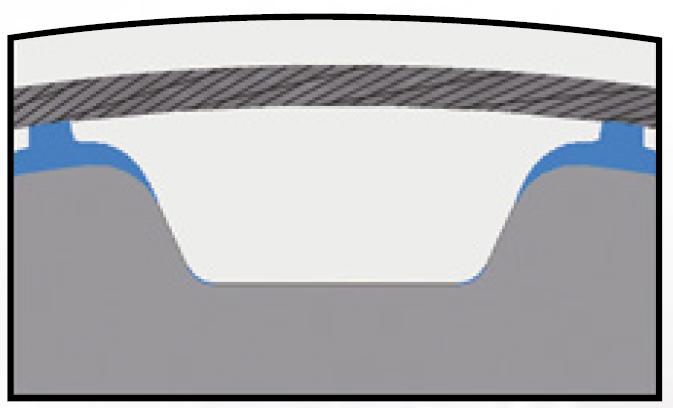

It is very important to consider the belt running direction as well as the span length upstream of the belt guidance. At least, the economic aspects are to be considered as flanges on small synchronising pulleys are more cost effective as flanges on large pulleys.

When using tension rollers the belt guidance can be positioned in the tension roller. Position a tension roller with flange such that a maximum span length results upstream of the guide infeed. (The preferably position of the tension roller is the slack span side).

With bi-directional drives the preferably position of the guiding tension roller is in the centre of the belt span. Short span lengths in front of the guidance infeed are to be avoided.

Further informations to the belt guidance on request.

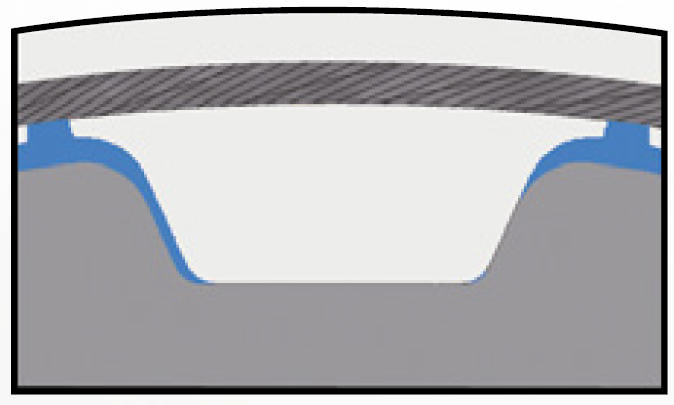

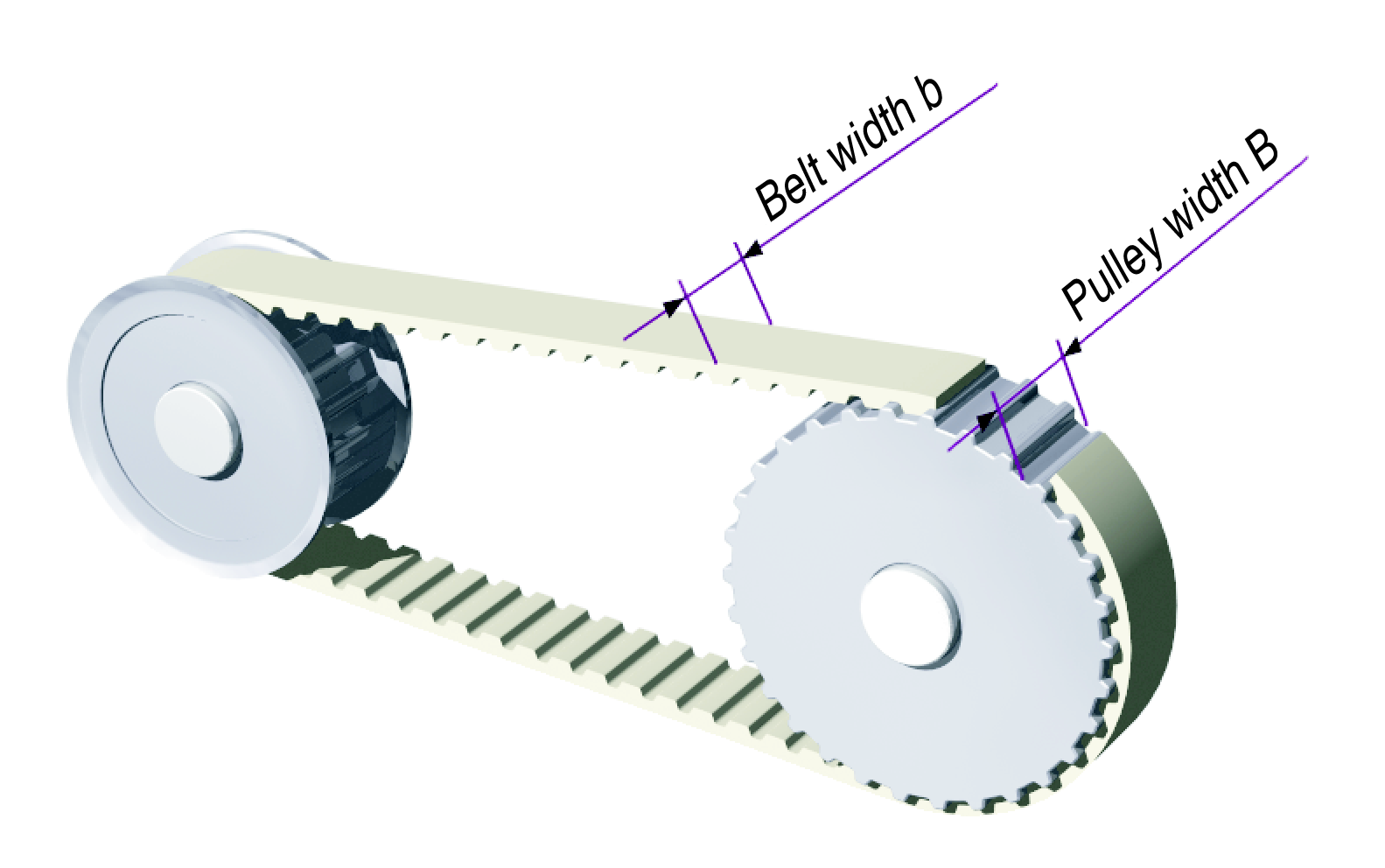

The belt width b is assigned a pulley width B each which guarantees sufficient lateral play. The "width clearance" is not especially dimensioned.

In special cases, e.g. with very long belt lengths or vertical axis positions, more than two flanges may be required.

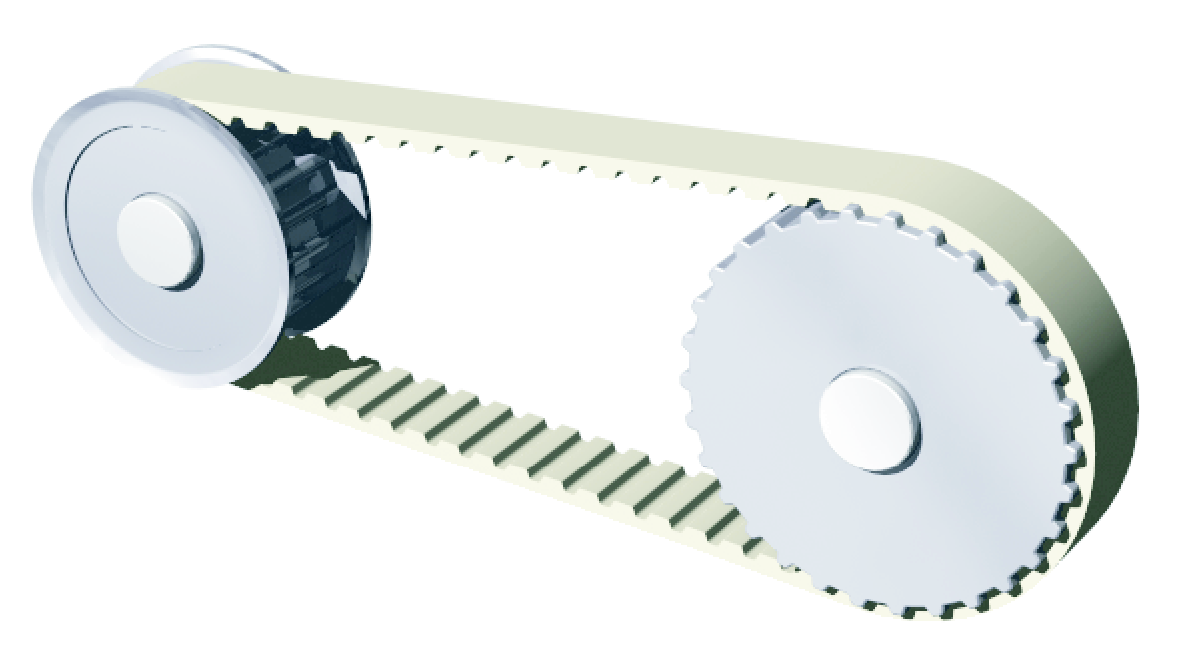

Tooth gap shapes

Timing belts are positive fitted drive elements. They work slippage-free with the respective synchronising pulleys. BRECO®, BRECOFLEX® and CONTI® SYNCHROFLEX polyurethane timing belts can be optimised additionally for a movement transmission with a low flank backlash. Please contact us for technical advice.

For some pitches, the SE or zero gap can be used for especially high requirements on the precision of the movement transmission.

Prerequisites for the application: Belt pitch size = pulley pitch size

Influencial factors of the pitch correspondence:

- Pre-tension force

- Meshing distance (ze )

- Load rate (rotational speed, dynamic behaviour...)

- Manufacturing tolerances