Construction and properties

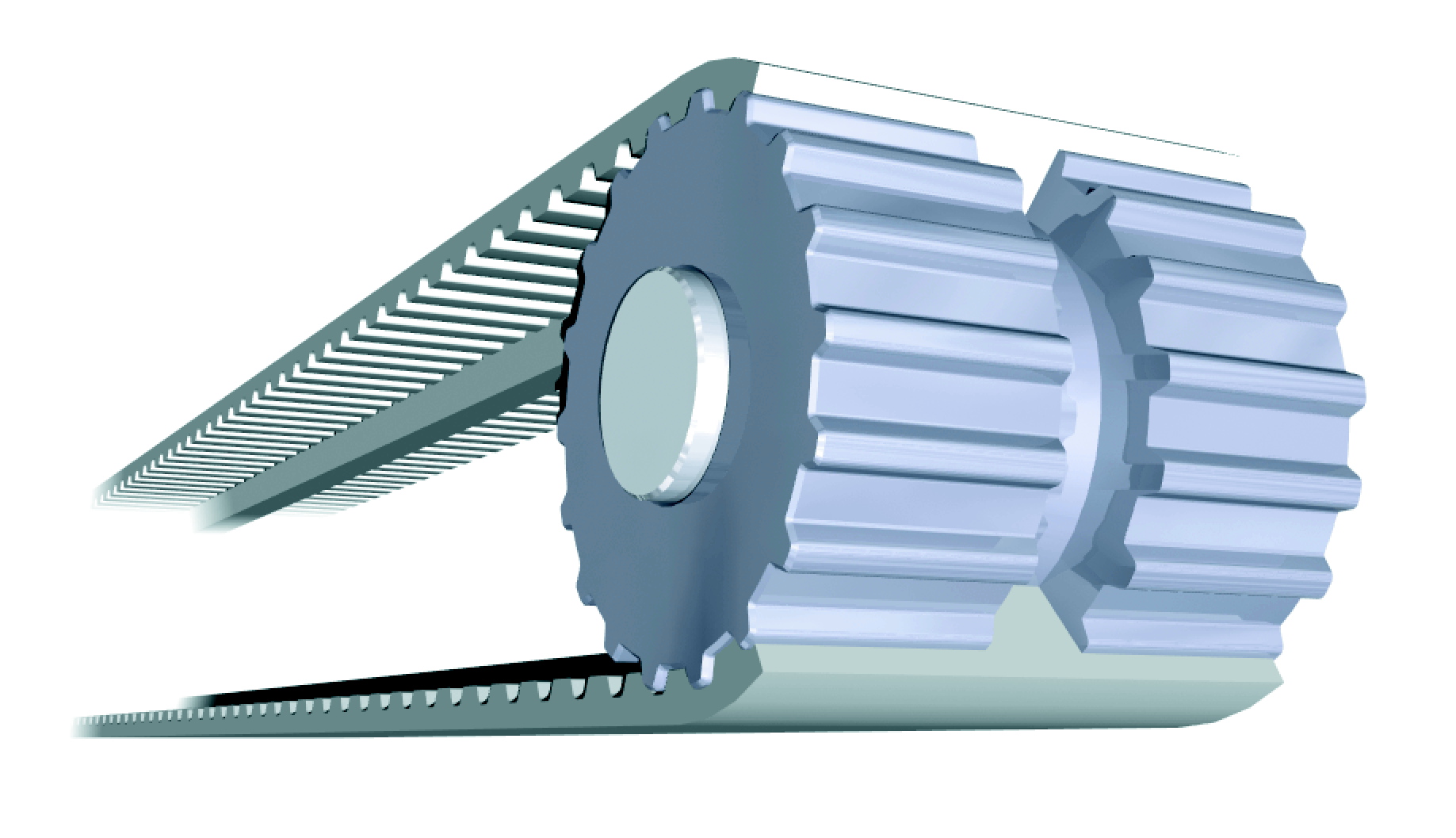

The combination of timing belts, poly-V-belts and steel cord tension members in one belt construction results in straight running synchronous belts. Their preferred fields of application include the transport and handling technology. The V-guide assures a straight belt run throughout the entire span length.

Self-tracking belts have ensued from the well known BRECO®, BRECOFLEX® polyurethane timing belt range. They are made of high tensile steel cord tension members. The timing belts are temperature resistant with ambient temperatures from -30 °C to +80 °C. Applications close to the limit temperatures (<-10°C and >50°C), however, might require adapted dimensioning. In this case please contact your Mulco Sales Partner.

The belts are resistant to petrol as well as simple grease/fats and oils. Their degree of efficiency amounts to 98%. Under extreme load and after a short run-in time, the pre-tension of the belts might slightly reduce by the tension members settling, making a once-only re-tensioning of the timing belt unavoidable. No post-elongation of the tension member is to be expected in continuous operation.

Corrections of the permitted load values are to be considered for deviations from the standard.

V-guide along tooth profile

- Straight and synchronous run

- Reliable belt guidance, unaffected by lateral forces

- Can be suded for any transport distances

- Can be used for a straight running material flow for indexing, separating and positioning

Self-tracking belts

BRECO® self-tracking PU timing belts ensure a secure straight run due to the V track integrated in the belt construction.

Transport and handling technology are the fields of application of these self-tracking belts. They are particularly suited in transport lines and transfer stations. Self-tracking belts are not affected by lateral forces.